Copyright © 2007 - 2025, Coachworks For contact data Click Here.

Copyright © 2007 - 2025

Copyright © 2007 - 2025,

Coachworks For contact data

Click Here.

The following was sent to the Karmann Ghia Club of North America's email list on September 21st, 2009 but included the data through the end of September 18th. To wit:

Hello All,

I know a lot of you have asked about the numbers, but just looking at the numbers would give you a very incomplete and, dare I say misleading, impression of what happened. So, ... I'm going to pick up our story from the previous update and carry through to completion so you have a proper idea of what the numbers represent and the context in which to understand them.

...Our last update was September 12th, a week before the vehicle actually "hit the salt." On that day, I had awaken to the sound of rain on the roof and had run outside at 2:30 AM or so to protect the tools, vehicle, etc. Some might recall that it was a significant rain and it continued intermittently for three days. The day before, I'd run the engine, put a video of it up on the web, and then had a serious delay with the starter.

After

the rain that morning - and my report to you - I worked on the transaxle some

more and by the evening, I had the gears mounted on their respective shafts

and the selector shafts adjusted. I used all the special "factory tools"

(actually they were intended for VW Dealerships) that existed for every job,

so it went reasonably well, but I was mixing and matching from several transaxles

of very different eras and the workshop manuals tell you _nothing_ about their

compatibilities. I did have Ron Jones' (of Ron's Transaxles: https://RonsTransaxles.com/)

advice, but there was some conflicting advice over which "rails" to

use.

After

the rain that morning - and my report to you - I worked on the transaxle some

more and by the evening, I had the gears mounted on their respective shafts

and the selector shafts adjusted. I used all the special "factory tools"

(actually they were intended for VW Dealerships) that existed for every job,

so it went reasonably well, but I was mixing and matching from several transaxles

of very different eras and the workshop manuals tell you _nothing_ about their

compatibilities. I did have Ron Jones' (of Ron's Transaxles: https://RonsTransaxles.com/)

advice, but there was some conflicting advice over which "rails" to

use.

So, I had to do a few things more than once in order to get the "mixing and matching" right. And, while (at least) four transaxle cores were involved, none of the "guts" (shaft assemblies) were done correctly! So, I had to catch the assembly errors of other people when I myself have only previously done Porsche 356 and early VW "split case" transaxles. (I had rebuilt a tunnel-type transaxle with someone else in the early '80s but only upon doing this by myself did I realize how little I had learned from that experience.) ...Catching these errors was a combination of very careful reading of both the early and late tunnel-type service manuals and the respective parts manuals to discover what parts had been left out or installed in the wrong order, along with careful disassembly to see what exactly had been done before. And, I had to measure things during the disassembly process, too, as well as the usual during-assembly measures.

It

was somewhere between midnight and 1 AM when I called it quits for the night

and then picked up the pieces again by about 6AM. I got to work on the differential.

I media blasted it as Ron had directed - it was an 8 bolt unit to go with my

8 bolt ring gear, spyder gears still installed. However, the 8 bolt R&P

core I'd used was from an IRS unit and therefore had the wrong bolts, so I used

the 6 bolts from the former swing axle differential that I'd taken apart. I

didn't have another swing type diff handy (only in another core), so I hunted

through a used bolts bucket until I found two suitable size and grade (grade

10.8) to make 8 total, though these were not drilled for safety wiring as the

other 6 were. -shrug- I ignored the lack of safety wiring in these two, mounted

them opposite for balance purposes and safety wired the others in two groups

of three.

It

was somewhere between midnight and 1 AM when I called it quits for the night

and then picked up the pieces again by about 6AM. I got to work on the differential.

I media blasted it as Ron had directed - it was an 8 bolt unit to go with my

8 bolt ring gear, spyder gears still installed. However, the 8 bolt R&P

core I'd used was from an IRS unit and therefore had the wrong bolts, so I used

the 6 bolts from the former swing axle differential that I'd taken apart. I

didn't have another swing type diff handy (only in another core), so I hunted

through a used bolts bucket until I found two suitable size and grade (grade

10.8) to make 8 total, though these were not drilled for safety wiring as the

other 6 were. -shrug- I ignored the lack of safety wiring in these two, mounted

them opposite for balance purposes and safety wired the others in two groups

of three.

When it came to shimming the R&P, I set the pinion depth easily enough, but had trouble with the differential S1 and S2 shims - nothing made sense. I had all the special tools except VW 298, if I recall correctly - and wasn't sure what, if anything, to do about it. And, the manuals were of _no_ help.

Moving on to other assembly tasks, I set about collecting up all the little pieces to put on the car. Some - most - of these little parts needed some cleanup / restoration, so, as time was running short, I decided to just "borrow" parts from another '59 Karmann Ghia whenever it would save time, and I'll replace them when this year's 36hp Challenge is done. This took most of the balance of the day. In the evening, Chris Morice came by and dug through more than 30 horns looking for any good 6v ones - or even 12v! We found ONE 12v horn! I recall forcing myself to bed at 1AM. I'm not sure but I think this was when Chris installed the _wonderful_ quality rear engine seal that I've stashed for just such an occasion.

In the morning, Monday now, I was feeling the shortage of time quite acutely so I was up at work at 5 AM. I called Aaron at about 8:15 and asked if he could help, and he said he could, so he showed up at about 9:30 to find me on the phone with Ron Jones. Ron told me he never used VW 298 and I should skip it, and he told me just how to proceed. Hearing Ron explain things it made so much sense and yet raised puzzles in my mind as to why the workshop manual was so opaque; just one or two sentences edited or added would have made all the difference!

... So, I got on with it, but was distracted throughout the day with other assembly tasks - helping Aaron keep properly targeted on only what the rules said we had to have done, or how Karmann Ghias differ from Beetles, etc. Somehow, by about 3:30, I managed to get the differential installed properly. And, Aaron had gotten a lot accomplished on other vital tasks, such as replacing a bad front drum, lubricating both front axles, adjusting all 4 link pins, and other mechanical tasks.

I

spent the evening working on getting the front and rear windshield installed

along with Larry Edson. After a bit of frustration, at least four attempts at

the rear glass - and over 23 hours of continuous work with only 4 hours sleep

the night before, I gave up, but Larry, understanding the vitality of the mission

continued on solo on the glass while I worked on other things, such as getting

the front hood lock and safety catch operable and collecting up parts for the

next day. Larry left at about 1:30AM and I went to bed...

I

spent the evening working on getting the front and rear windshield installed

along with Larry Edson. After a bit of frustration, at least four attempts at

the rear glass - and over 23 hours of continuous work with only 4 hours sleep

the night before, I gave up, but Larry, understanding the vitality of the mission

continued on solo on the glass while I worked on other things, such as getting

the front hood lock and safety catch operable and collecting up parts for the

next day. Larry left at about 1:30AM and I went to bed...

Tuesday was another early morning, though not quite as early, and the cold front had passed, the rains having finally finished their on again off again cycle. I installed the ignition switch, headlight switch, wiper switch and other key bits, and when Aaron arrived, I handed off wiring tasks to him but instead, the more vital question of getting the transaxle installed pushed to the fore. You'd think mounting up two drums wouldn't take so long, but I wanted to finish some things I should be doing and unfortunately, Aaron hadn't ever had the experience of collecting up the right bits from parts bins and continual mismatches kept him from completing the installation of two brake drums (complete to the cables) until about 4 PM. He experienced about every mismatch possible, such as wrong width shoes, too-long shoe retaining pins, etc. Meanwhile, I installed the headliner, gauges, and a number of smaller parts.

Together, through the day, Aaron and I worked on many mechanical issues such as the master cylinder (replaced w new), among other related issues.

The 36HP challenge was supposed to start the following morning, but we got word of a rain-delay and were told we wouldn't have full data for another day but we knew that at the very least there would be no racing Wednesday and that we'd know the following morning, Wed. morning, at 10AM Mountain Time, what the story would be. So, the rain delay was good for us, I thought. We kept working! That night, after Aaron left, I installed the transaxle but had trouble; it wouldn't go in! I struggled through the evening, deep into the night.

Wednesday AM, I called Ron again and he politely listened to my expletives regarding the trans not fitting and my query about what mounts I was supposed to use, and he then told me that I was supposed to be using the '62 through '67 Type II front mount. Damn. Didn't have one. But I did have one from a '50's era split case which could do in a pinch! (It has M8 studs not M10, but for this use-scenario, M8 was fine.) So, installed it.

It was at this time we got word of the Rain Delay and the plans out at Bonneville; I was told Racing would still be four days, but instead of Wednesday to Saturday, it would be Thursday to Sunday. Therefore, travel would still work and I'd not miss any racing. Days would end at 6:30 PM except for the last day when it would end at 4PM. This meant leaving that night would mean no missed racing! At the time, this still seemed possible, though there was a lot of work to do... We pushed on _hard._

Aaron was unavailable that day so Chris Morice came by again and helped me bleed the brakes. While he helped with another minor thing or two (grateful for ALL the help), I think it was about then that he had to leave.

I noticed that the throwout bearing clips didn't fit this aftermarket cross-shaft tightly, so I safety wired them, and other unsundry transaxle related tasks...

I

then focused on the fuel system. I found a place to mount the fuel pump and

pressure regulator in the front, mounted directly to the front axle's upper

tube, safe from road debris but accessible from the spare tire well. I mounted

up the starter, sans bushing (!!), but didn't yet have the battery wiring done.

So, I focused on that. I ended up running two 6V Optimas, sat side-by-side inside

a store-bought battery box, connected in series to make 12v with a special +

terminus at the + on the low-position battery so it could both provide 12V AND

6V, as desired. I did this because we did not yet know what voltage the car

would end up being because we had no working horn yet! ...And I then made up

a stock-looking retaining strap as I knew it would pass tech.

I

then focused on the fuel system. I found a place to mount the fuel pump and

pressure regulator in the front, mounted directly to the front axle's upper

tube, safe from road debris but accessible from the spare tire well. I mounted

up the starter, sans bushing (!!), but didn't yet have the battery wiring done.

So, I focused on that. I ended up running two 6V Optimas, sat side-by-side inside

a store-bought battery box, connected in series to make 12v with a special +

terminus at the + on the low-position battery so it could both provide 12V AND

6V, as desired. I did this because we did not yet know what voltage the car

would end up being because we had no working horn yet! ...And I then made up

a stock-looking retaining strap as I knew it would pass tech.

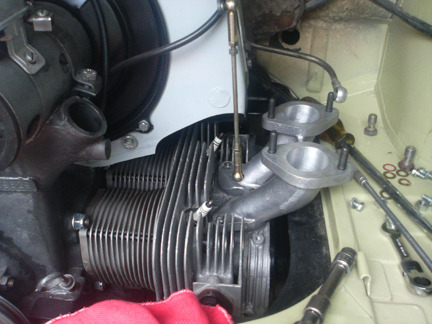

I then tried to install the engine and struggled mightily. I knew the carburetors had to come off, but I tried installing with the manifolds mounted to save time. Eventually I realized they had to come off, so I called it quits because I was _so_ tired and I didn't want make a mistake and drop anything down the intake system! The last thing I did for the night - at about 1AM, was put a second coat of paint on the fabricated battery retaining strap. OK, missing Thursday might still be OK as that still left three days of racing...

Thursday

AM I got the engine installed by, just as predicted, removing one intake manifold.

What A Pain! But it was now clear why the sheet metal ("tin") was

the way it was: specifically to provide access to remove and reinstall the manifolds

in-situ because it _must_ be done to get the engine in! (or out!) I then focused

on getting the oil system installed - you know, the full-flow oil filter, external

oil cooler and it's thermostat - and all the hoses. I cut the hole through the

rear tin ("breast plate"), threaded the fasteners together, mounted

the oil filter, mounted the oil cooler, etc. Aaron helped with the oil cooler

mounting bolts and we had to move the cooler leftward as it was in the way of

the starter in the original position I'd chosen. -frown- ...I don't recall at

the moment what else Aaron was doing but he helped from about 10:30 to about

3:30, if I recall correctly. I, meanwhile, worked into the wee hours once more,

got the tail lamps installed and the last chore picking out headlight and turn-signal

bulbs that work with 6V.

Thursday

AM I got the engine installed by, just as predicted, removing one intake manifold.

What A Pain! But it was now clear why the sheet metal ("tin") was

the way it was: specifically to provide access to remove and reinstall the manifolds

in-situ because it _must_ be done to get the engine in! (or out!) I then focused

on getting the oil system installed - you know, the full-flow oil filter, external

oil cooler and it's thermostat - and all the hoses. I cut the hole through the

rear tin ("breast plate"), threaded the fasteners together, mounted

the oil filter, mounted the oil cooler, etc. Aaron helped with the oil cooler

mounting bolts and we had to move the cooler leftward as it was in the way of

the starter in the original position I'd chosen. -frown- ...I don't recall at

the moment what else Aaron was doing but he helped from about 10:30 to about

3:30, if I recall correctly. I, meanwhile, worked into the wee hours once more,

got the tail lamps installed and the last chore picking out headlight and turn-signal

bulbs that work with 6V.

I got up early on Friday, started with maintenance on Babe, the Blue Ox (tow vehicle), worked on the wiring, and then I aligned the suspension. I knew this would not take long because the rear was already done and I had previously reinstalled the spindles and set the toe, but had left the lock-plates un-folded "just in case." I actually have a full Bosch chassis alignment jig, specifically designed for the old swing-axle VWs and Porsches. Luck was with us at last as there was finally nothing to do but check the alignment and fold over the lock tabs after being satisfied with the existing toe.

Meanwhile,

I called Aaron and asked him to help with the wiring. I started with the inner

door glass felts as I didn't want to ruin the glass in transit and knew it would

otherwise be forgotten. I then devised a fantastic method of attaching the fire

extinguisher: I used an "aircraft" seat-belt that had no sewn ends,

fitted one sides's strap around the support for the rear seat, fitted the latch

piece to the same webbing and then latched the buckle around the extinguisher,

attached to the rear seat's forward support, just behind where the right passenger

seat would go, if installed.

Meanwhile,

I called Aaron and asked him to help with the wiring. I started with the inner

door glass felts as I didn't want to ruin the glass in transit and knew it would

otherwise be forgotten. I then devised a fantastic method of attaching the fire

extinguisher: I used an "aircraft" seat-belt that had no sewn ends,

fitted one sides's strap around the support for the rear seat, fitted the latch

piece to the same webbing and then latched the buckle around the extinguisher,

attached to the rear seat's forward support, just behind where the right passenger

seat would go, if installed.

By the time Aaron arrived, I had the front turn signals hooked up and some of the headlight wiring sorted but they didn't work. And, there were other tasks. He came later than usual, 10:30 as I recall, and by then I was working on completing the oil filtering and cooling system. Aaron found a fuse box problem and after sourcing several, finally found a good one and got it installed. He then mounted up the wiper motor and struggled to get it working. Eventually, he got the correct wiring information from a loose switch as he couldn't see the numbers on the installed one.

Now what? Found a Porsche 356 6v horn that worked! Aaron tried a proper horn relay and, after finding it bad, he wired a "cheater" circuit directly to the horn, so, if called upon, I'd blow the horn by grounding one wire inside the cockpit. Yes, this was a racing _requirement_ by our class rules! (as were most of the other tasks we were working on.)

I tried to move Babe over to hook up the towing rig - no time for even a single test drive! And Babe started and then stopped - the kind of stop that says it's electrical. The cap and rotor had run into each other because I had failed to reattach the cap's bails following the tune-up. ...After much delay, including diagnosis from Aaron with his high-tech (expensive) VOM, we determined that it was likely contamination of the points. So, I removed them, and installed a new set of ign. parts, and it restarted fine.

-heavy-sigh. The Last Day Possible for Preparation was burning! FINALLY time for startup. Almost: the fuel pump needed a ground wire, the hand-brake needed installation and adjustment, and, and, and... Time for the steering shaft, turn signal switch wiring, speedo, tachometer, and, and, and... The toe-in adjusted, fuel pump ground mounted, fuel hoses routed, steering gear oil topped up, master cylinder all done, it was time for the fuel tank and reserve lever. Top up with gasoline! Oops - spillage!

Time for initial startup. During the fuel system check, the damned left hand carburetor's banjo fitting failed _again._ (I don't recall if I already reported that in early testing I had found it failed and I had re-soldered it about five times while on the dyno stand before I finally had it fixed - well, it failed _again._) So, an executive decision: Cut it! I cut out the leaking banjo because I could not solder it with a carburetor full of fuel only 5mm or less away, in the car no less, and the solution was another, previously soldered banjo fitted with a tiny stint of fuel hose. ...Along the way I found that carb's float level was loose and had changed, so I reset it, snugged the adjustment and rechecked the right one. This was among seemingly hundreds of tiny chores, all done with an eye towards the clock - time was running out!

Mount the driver's seat, a little grease! Drill the last hole, mount the seat belt!

Then, all systems were go, so I started the engine. Ignition - no fuel leaks, check! START! Oil pressure, check! Oil fittings dry - CHECK! READY!

BANG!

Damn; the external oil cooler _exploded._ It looked like five quarts of oil on the damned ground under the Ghia. It was probably only a quart or two at the most - still a massive oil spill. -big-frown-

Executive decision; Use one double-ended, male-male fitting to connect the oil cooler hoses together to simply bypass the cooler!

FINALLY,

at about 3:30PM, we had everything working as per the rules that were asked

of us, the towing hardware was attached and I declared it time to send Aaron

on his way while I pack and get out the door.

FINALLY,

at about 3:30PM, we had everything working as per the rules that were asked

of us, the towing hardware was attached and I declared it time to send Aaron

on his way while I pack and get out the door.

I topped up Babe's oil level and loaded everything I could conceive of that I might need into Babe or the Ghia, and then took a shower. Then, personal belongings, the GPS, phone, camera, hat, HELMET! I took the moment, on advice of Burlile and Britt, to check the web site - no changes or notices - and print all the forms I could find as it would save time later.

I was out the door by about 5PM...

FINALLY on the way!

This marks the end of the updates. The final installment, The Salt, coming forth with!

Richard

P.S. Photos and more here:

https://ghiacoachworks.com/share/denzel_lsr.html

RT