Copyright © 2007 - 2025, Coachworks For contact data Click Here.

Copyright © 2007 - 2025

Copyright © 2007 - 2025,

Coachworks For contact data

Click Here.

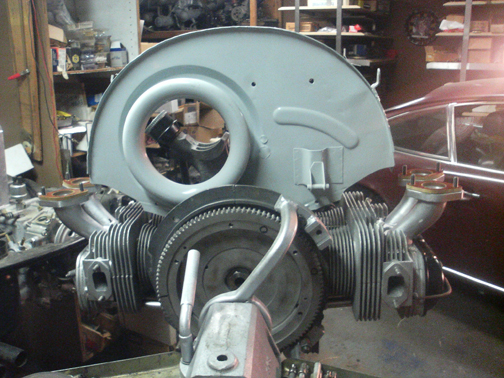

The cooling system consists primarily of the cooling fan and the sheet metal that directs air, as well as the parts of the oiling system that cool the oil.

The

Fan

The

Fan Another lesson they have for us is that stock fans sometimes explode at high RPM.

We are reducing the turning speed of the fan by using a small diameter crankshaft pulley, and a large diameter fan pulley, essentially following in the footprints of Porsche as their engine developed through the 1950s.

We are reducing the horsepower required by the fan itself by reducing the number of blades.

We are addressing the possibility of the fan exploding by welding the formerly crimped connections between the blades and the fan's discs.

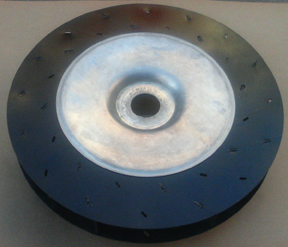

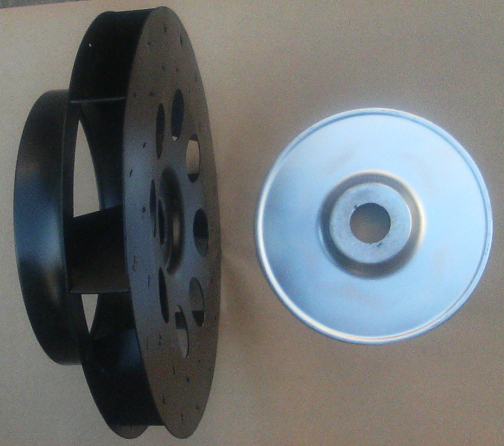

Most people are unaware that the output of the fan can be improved by being certain to include a block for all the holes in the fan's main disc. All fans with big circular holes around the center hub have available a little piece of tin that closes these off, as in these images - different fans have a different piece, and we are aware of at least three versions of this part.( The part must fit the fan perfectly.)

You should always check out the installed fan by turning it in the housing, fully assembled:

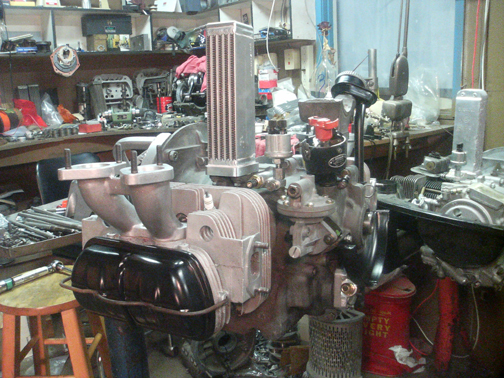

We mounted a second auxiliary oil cooler above the transaxle, but this is the one inside the fan housing. This is a modern production aluminum cooler, made of very pure aluminum in the vertical passages in order to obtain maximum heat transfer, while the rest of the structure is made up of a more durable alloy of aluminum. It's availble from the Porsche 356 market and fits VW crankcases as well. It isn't cheap, but is of very high quality.

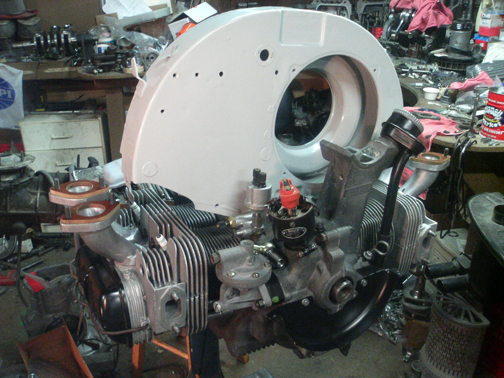

Because our engine will likely not be able to be fully warm at the start of every run, we were concerned about this problem. At some point in the late 1950s, however, the Porsche fan shroud incorporated the throttle linkage as an integral system. This system provides a rotating bar on the firewall side with "over the top" arms and down-links to the carburetors - these don't have the expansion problem - as engine width changes with engine temperature, the linkage remains set because the down-links have ball sockets that accommodate the change. Therefore we decided to use a Porsche 912 unit, nearly identical to the Porsche 356 except without the carburetor heating parts and with an extra hole designed to attach the top of the internal oil cooler to the shroud itself. We plugged this extra hole.

We decided not to run the lower cylinder shrouds because, firstly, we'd have to make them and it seemed easier to just make the vital bits, and secondly because there will be less aerodynamic drag without them. ...Here are the parts we're leaving out:

Here are all the pieces of tin we either had to make from scratch, or significantly modify: