Copyright © 2007 - 2025, Coachworks For contact data Click Here.

Copyright © 2007 - 2025

Copyright © 2007 - 2025,

Coachworks For contact data

Click Here.

The following was sent to the Karmann Ghia Club of North America's email list on August 22nd, 2009:

Well Folks,

anyone who thinks "blueprinting" an engine is easy, or who thinks that "going racing" is a slam dunk is someone who hasn't done the work! Especially if its Vintage!

Oh _sure,_ In Theory, everything is straight forward.

So, our saga picks up with a brief recap for context starting where we were this past Monday or thereabouts. I thought I had in hand everything to assemble the engine. There were no other known issues, so, assemble the crankcase! Oops, not so fast! Three problems: Oil passage missing in a new main bearing (!), the new camshaft didn't fit and both the cam and the case were "at fault," and, the specific crankshaft to be run didn't clear the crankcase properly even though an "identical" one did. And I had already put case-sealant on, so everything had to be cleaned _again._

All

those problems sorted, the bottom end was assembled, and, excited at that advancement,

I got cracking on mounting up everything else for a "mock assembly"

- which you can see on the web. This is where things left off from the last

update.

All

those problems sorted, the bottom end was assembled, and, excited at that advancement,

I got cracking on mounting up everything else for a "mock assembly"

- which you can see on the web. This is where things left off from the last

update.

Next up, the top end. As I had already spent a lot of time selecting shims doing trial assemblies, that should go smoothly. I checked the ring end-gaps - they're very well made and while I might have quibbled with them a little, they were well within tolerances. So, mount the rings and check the ring side clearance against the ring lands on the pistons. I was unhappy to find more clearance than I usually see. So, out comes the manual; Hmmm... Two pistons are close to the small end of the new parts tolerance range (very good) and two pistons are just past midway (not so good, but acceptable). ...So, mount the cylinders!

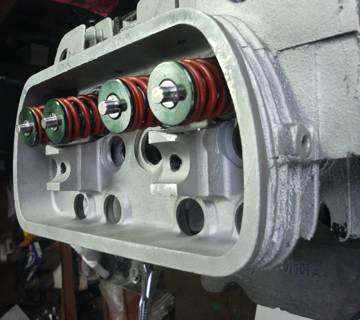

Now the heads.

So much time had already been spent on the heads I knew what was left: I had not balanced both chambers because without the valves I was having a hard time getting good measurements of the chamber volumes. So, the valves had to be assembled and the only things missing were the spring seats - essentially these are shims - like precision washers - to set the installed-length of the spring exactly. This is called, "setting the installed height". Oh, and the spring seats aren't quite only shims, they also help keep the springs in place so the spring base does not move around and "walk" on the head - this would not only alter the spring pressure but could cause things to bind up somehow and cause damage. (I've seen it before on other engines.) And, the steel springs vibrating against the aluminum heads causes the aluminum to wear and put metal particles into the oil.

So, I went to make the spring seats from some 1 1/4" solid steel bar stock. This was when I found out that my lathe"took a crap", to use John Copello's expression. -frown- The spindle that holds the chuck was loose and the spindle - or rather the work-piece! - hopped up, walked over the tool on the end, trashed a $20 piece of carbide (the bit in the lathe's tool holder), and damned near caused an injury! I was just lucky I was exercising lathe safety protocol! ...So, now what? One machinist friend said he'd help [by making the needed parts] but then declined to answer the phone to get the specifications at the agreed time - had other priorities that day, he said later. Another friend who's less of a machinist but who has a lathe said he'd let me use his - and he was going to help with other issues, too.

(SPECIAL NOTE: I got this lathe barely a month ago from John Copello's dad, Larry, in cahoots with Larry's friend Al. Al admitted to having just taken the spindle out of the lathe and that afterward he had not put any load on the machine, just spun it up. So, he had merely failed to adjust it properly. He is due to come here and fix it this coming Thursday. Meanwhile, the lathe is useful for some very light-duty work.)

So,

the next day I gathered up the flywheel and pressure plate and a few other goodies

and went to this friend's place. He was very busy but showed me how to use his

balance machine and I balanced my flywheel to perfection, mounted up the pressure

plate, and then balanced the two together. But by the time I was done, we didn't

have time to get the spring seats made, so, I thought about "plan C".

So,

the next day I gathered up the flywheel and pressure plate and a few other goodies

and went to this friend's place. He was very busy but showed me how to use his

balance machine and I balanced my flywheel to perfection, mounted up the pressure

plate, and then balanced the two together. But by the time I was done, we didn't

have time to get the spring seats made, so, I thought about "plan C".

In the morning I had a bright idea: use an old 36hp spring retainer - it's the right basic size. Just drill through a hole big enough so it would slide over the valve guide and we should be done! Did it, slid it on, and it worked! Great! The retainers were designed to fit the spring, just on top. The hole through the middle slid onto the guide just fine and provided a wall that guided the inner spring on where it needed to be. Perfect!

...Um... except for the fact that it had a slightly raised inner ridge that fit the inner spring perfectly, and this was a problem because it altered (shortened) the installed height of the inner spring. Damn. Oh, this was no minor problem; it would actually cause the inner spring to bind up solid. That would be a serious disaster.

This

caused much fretting, concern, and calling of people with more experience than

me for their opinions. One choice was to simply omit the inner spring. Trouble

with that is the inner spring, weak as it is, is actually needed to boost the

pressure into the known safe zone - without sufficient pressure the cam follower

may not remain in contact with the camshaft lobe at very high RPM and thereby

"float the valves." Floating is very destructive of the parts and

it also causes loss of both power and torque. Find alternate springs? I went

hunting through all my springs - many surprises there, but nothing useful for

this project. ...You can't just go out and buy a set - nobody sells "Denzel

valve springs", except maybe me when this is over!

This

caused much fretting, concern, and calling of people with more experience than

me for their opinions. One choice was to simply omit the inner spring. Trouble

with that is the inner spring, weak as it is, is actually needed to boost the

pressure into the known safe zone - without sufficient pressure the cam follower

may not remain in contact with the camshaft lobe at very high RPM and thereby

"float the valves." Floating is very destructive of the parts and

it also causes loss of both power and torque. Find alternate springs? I went

hunting through all my springs - many surprises there, but nothing useful for

this project. ...You can't just go out and buy a set - nobody sells "Denzel

valve springs", except maybe me when this is over!

Think, think, think. As I have a few "spares" of the early VW spring retainers, I did some experimentation. I ended up using an end-mill (normally used in a milling machine) in the lathe to cut through the already bored "seat". This gave two parts, one a washer big enough (almost) to go _around_ the inner spring, and a cone shaped part that could mount to the valve guide and in effect make it 2mm larger in diameter, and thereby perfectly fit the inside of the inner spring, thus serving to keep it in place! Wow! Then, just a little work on the mill table (could have used the lathe, too) to put through it a de-burring tool (intended for a different purpose) which opened up the hole just enough so the inner edge of the former spring retainer would now go around the inner valve spring! Double wow!

OK, so this means one former valve spring retainer became two parts, a spacer to fill the void between the inner spring and the valve guide (and thereby keep the inner spring in position) and a second spacer that fits _perfectly_ around the inner spring's last winding which then supports the outer spring and gives it a different (shorter) installed-height!

Allright, now, something to protect the aluminum head from all this moving steel and to set the final installed height. Hmmm...

I found that VW link pin shims are consistently 0.5mm in thickness and have an inside diameter that would work - but the outside was 32mm and the head won't take but 31. So, they'd have to be turned down (on the lathe). To do this, I found a steel sleeve used in housing / building construction that perfectly fit the inside diameter of the shims and that fit (reasonably closely) a bolt I had on hand of sufficient length. I cut a length of the steel sleeve just barely shorter than the stack of the estimated number of valve shims required, put the link pin shims onto the steel sleeve, added a pair of washers to spread the load and tightened the bolt - thus, I made a mandrel to mount the shims in the lathe! I then turned them down on the lathe and PRESTO! I had a stack of special 0.5mm valve spring shims!

Whew!

Install

them!

Install

them!

Sorted through all the valve springs and matched up pairs of inner and outer springs - it just happened by luck that each group had four each of stiffer and less stiff springs, so these were grouped to give the intakes more spring pressure because the intake valves are heavier. Then, carefully assembled all the valves. No problem in assembly... This was last night at about 8:30 PM... Heck, I thought, should have the whole thing done, valve cover to valve cover by maybe 10PM and surely by midnight!

Back to the combustion chamber volumes. One head only needed a trim of some 0.2 ml (that's milliliter) - not much! I got it done on the first attempt - exactly perfect! The other one didn't go so well. ...You can't put the metal back in, so you remove it reluctantly, trying to make the smaller combustion chambers as big as their neighbor. So, you take a bit out, measure, take a bit more, measure, etc., until they match. Take out too much and you're screwed!

I had already measured them and knew how much to remove from where. But when I removed some material from the one chamber, it measured _smaller_ than my previous measure, by a lot! Took out some material and measured, repeatedly, in the iterative process described above. It never seemed enough. For a sanity check, I remeasured the opposite side. Yup, the measurements agreed. Hmmm. Take out some more...

Eventually, after some _twenty_ cycles of remove, measure, remove measure ad nausieum, I looked at the chambers and said to myself, what the heck is going on here?! It _can't_ be this different!

It then dawned on me: my machinist friend who installed the new valve seat had done a rushed job and hadn't bothered to match up the new seat to the older remaining seat's depth. Thus, the new valve on the new seat stuck very much more deeply into the combustion chamber than its adjacent mate. _That_ was the problem! Confirmation: Casual eyeball measurement showed the valve stem stuck some two millimeters or more into the "rocker box." It was _obvious!_

Great. So now I've taken material out of the head I can't replace trying to chase the wrong problem. Well, at least I was taking material out in a way that should improve air flow!

So, I dug out _my_ valve grinding stones and promptly found that the stones I have are all too large to work with these heads! _DAMN_

While I was at it, I realized I hadn't taken this into account when figuring out the valve spring installed heights, so with some dread, I got out the measuring tools and measured the installed heights - would the unequal valve stem heights get me in trouble?! Of course, I have long known that you need to watch out for (un)equal valve stem heights, but I guess in all the push against the calendar I overlooked this fundamental.

But Great News Here: By nothing but dumb luck ('bout time I get some!), out of eight possibilities, I had measured the shortest assembly and therefore, while no, they are not all the same, some off by as much as two millimeters (!!), at least, they're all fixable by making and installing some more of those converted link pin shims. AND I REALIZE I'm VERY lucky, that if I had used a longer assembly as the example, I would likely have never noticed that the other springs were going to be in big trouble when the coils bound up! In short, disaster narrowly averted. And, while this is taking some time, it's going to be _perfect!_

Today I'm going to see if Jerry is working at The Buggy House (or is it now Buggyhouse Motorsports?) and if I can borrow the right valve seat cutting stones (do it at his shop!), or if I have to go to Plan C on this one, too...

Getting it done, and done right,

Richard