Copyright © 2007 - 2025, Coachworks For contact data Click Here.

Copyright © 2007 - 2025

Copyright © 2007 - 2025,

Coachworks For contact data

Click Here.

The following was sent to the Karmann Ghia Club of North America's email list on August 12th, 2009:

Hi Ghia Guys and Ghia Gals,

things have been kind of quiet on the list, and, as I can't start work yet

as I'm waiting for clean work-clothes to finish in the wash, I thought I'd

let you all know that what's happening with the Salt Racer.

For those who may have overlooked or forgotten, there's a new category of Land Speed Record (LSR) available this year specifically for the Karmann Ghia. There are five divisions and all of them must have a "36hp" based engine. The divisions are: SS "stone stock", SSS "super stock Single" (like Formula V), DSS "Dual Super Stock" (for dual port engines, eg Okrasa, Denzel, excluding Porsche heads), K36 "Kompressor" (supercharged - aka Judson, etc), and NA36 "New Age" (may use younger equipment for many components). Find out more here: https://www.burlyb.com/

I intend not only to compete but to set a record - I think I have a good chance! In fact, the calendar may be my greatest competitor! Racing starts on the Bonneville Salt Flats on September 16! That's almost exactly one month from today.

I'm

campaigning a 1959 Karmann Ghia Coupe - a two-tone bamboo / dark green (roof)

vehicle. I was going to sell the car but decided to race it and then sell it

as the current Ghia LSR holder! I'm competing in the DSS category with a 1600cc

Denzel engine. The awareness and decision to do this came very late and I wasn't

as ready as I thought I'd be and I needed to call upon some vendors to help

with a few things. In particular, while I did other machine work on the cylinder

heads, they needed the combustion chambers clearanced for the special high-compression

pistons, the intake manifolds fitted and then the assemblies "flowed".

This "less than a day's work" took an elapsed time of 6 weeks! During

that time, I found new (ultra rare) valves and had to find possible valve springs,

carefully measure spring rate, coil bind height, check versus possible installed-heights,

find matching spring retainers, and I even had to commission the manufacture

of valve keepers as I only had two! And, of course, all the more typical challenges

of finding appropriate cylinder shims, making intake gaskets, and so forth.

Oh, and lets not forget fabricating an exhaust system from various available

donor parts from a system someone else started but didn't finish.

I'm

campaigning a 1959 Karmann Ghia Coupe - a two-tone bamboo / dark green (roof)

vehicle. I was going to sell the car but decided to race it and then sell it

as the current Ghia LSR holder! I'm competing in the DSS category with a 1600cc

Denzel engine. The awareness and decision to do this came very late and I wasn't

as ready as I thought I'd be and I needed to call upon some vendors to help

with a few things. In particular, while I did other machine work on the cylinder

heads, they needed the combustion chambers clearanced for the special high-compression

pistons, the intake manifolds fitted and then the assemblies "flowed".

This "less than a day's work" took an elapsed time of 6 weeks! During

that time, I found new (ultra rare) valves and had to find possible valve springs,

carefully measure spring rate, coil bind height, check versus possible installed-heights,

find matching spring retainers, and I even had to commission the manufacture

of valve keepers as I only had two! And, of course, all the more typical challenges

of finding appropriate cylinder shims, making intake gaskets, and so forth.

Oh, and lets not forget fabricating an exhaust system from various available

donor parts from a system someone else started but didn't finish.

The roof got painted last Wednesday it went very poorly - dust in the paint. Today, this morning, I hope to find out if that paint can stay or if I have to re-shoot it. It _may_ just turn from a two-tone vehicle (dark green roof, "bamboo" yellow/green from the "belt-line" down) into a single-tone paint job because of time.

Today we are to paint the bamboo color - second coat. Larry Edson is helping and he will show up around noon. Prior to that I am finishing up the "preparation work", such as ensuring that every square millimeter is perfectly smooth, "straight", and covered in appropriate primer - and clean and absolutely dirt and dust free.

Yesterday I worked about 10 hours on the same things (!!) including especially the "paint booth" - if you can call it a paint booth.

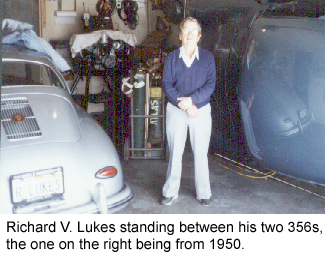

Amazingly enough, an old friend, now deceased  (Richard

V. Lukes), introduced me to a world-class camshaft designer. This fellow teaches

camshaft design and internal combustion engine mechanics at Stanford University

and De Annza College, and has designed - and ground - camshafts for many Land

Speed Record Holders. He is really one of the best in the world and does high-end

racing camshaft design work for many famous teams, like Ferrari, Toyota, among

many others. And, I presume because of my association with our mutual friend,

he agreed to design and grind the camshaft for me - for $100! Heck, you can't

get a STOCK, modern camshaft for that! (Note: He did charge me $185 for a brand

new billet to turn the cam grind onto, but that's the going rate others charge,

and he offered to put it on my own core and skip that charge if I chose.)

(Richard

V. Lukes), introduced me to a world-class camshaft designer. This fellow teaches

camshaft design and internal combustion engine mechanics at Stanford University

and De Annza College, and has designed - and ground - camshafts for many Land

Speed Record Holders. He is really one of the best in the world and does high-end

racing camshaft design work for many famous teams, like Ferrari, Toyota, among

many others. And, I presume because of my association with our mutual friend,

he agreed to design and grind the camshaft for me - for $100! Heck, you can't

get a STOCK, modern camshaft for that! (Note: He did charge me $185 for a brand

new billet to turn the cam grind onto, but that's the going rate others charge,

and he offered to put it on my own core and skip that charge if I chose.)

This camshaft is tailor made specifically for this engine in this application. Interestingly, he had me gather up _all_ the engine parameters and "do the math" first, then bring it to him. I came to him with proposed camshaft lift and pointed out various things in the data and made some timing proposals - specifically that the exhaust was unusually robust and perhaps needed a different profile than the usual. In the end, he said he ran the data through his computational models and confirmed my suggestions - he went with my lift and he developed a separate profile for the exhaust, just as I suggested! Very Cool.

Of the completed work he remarked that the computer models say the camshaft

will bring on strong torque from 2000 RPM to just past 6000 and

that peak torque should be around 4000 RPM with peak HP at about 5500. And,

he said, it will be a "very streetable" camshaft, with nice idle

characteristics.

I get the camshaft tomorrow and anticipate being able to assemble the engine - at least valve cover to valve cover - on Thursday or Friday. The 16th gives us exactly one month to not just finish the Ghia but get ourselves up to the salt and tune the engine for altitude - 4200 feet above sea level.

DO NOTE that this will be only the second known example of a running Denzel engine known to the Denzel community (such as it is). The odds of there being another one on the salt "approaches zero."

Meanwhile,

I have to get the transaxle (gietriebe?) ready. In this case, I thought I had

it already solved but it turns out that the transaxle I was planning to use

is not quite what's needed - there's a better fourth gear available I hadn't

known about previously. I'm going to leave the one I have already fully assembled

"just in case," and will be tearing down two transaxles to build one

"perfect" one - perfect in this case means having all the correct

gearing and _used!_ bearings and synchros! The reason I'll be doing all the

work of a "completely rebuilt transaxle" but without putting in new

parts for all the things that wear (excluding the gears themselves) is because

there's no time to "run-in" the parts and get them to loosen up. It's

like a new car's "break in period" - there's no time (mileage) for

that, so reusing good used parts has the same effect.

Meanwhile,

I have to get the transaxle (gietriebe?) ready. In this case, I thought I had

it already solved but it turns out that the transaxle I was planning to use

is not quite what's needed - there's a better fourth gear available I hadn't

known about previously. I'm going to leave the one I have already fully assembled

"just in case," and will be tearing down two transaxles to build one

"perfect" one - perfect in this case means having all the correct

gearing and _used!_ bearings and synchros! The reason I'll be doing all the

work of a "completely rebuilt transaxle" but without putting in new

parts for all the things that wear (excluding the gears themselves) is because

there's no time to "run-in" the parts and get them to loosen up. It's

like a new car's "break in period" - there's no time (mileage) for

that, so reusing good used parts has the same effect.

Even though I have built transaxles before, yesterday I spent several hours going through the big items I'll need to do this transaxle with two different experts. Each had something valuable to add. The first taught me how to determine what's inside a transaxle without taking it apart - so I can save time selecting cores, and the other taught me about what combinations of gears to expect, what teeth counts and types are for which gears (eg. if they're fine teeth and you count 27 it's .82, but if they're course, it's .89), what gears were common for what years, and some of the finer points of ensuring the used parts are actually worthy of being put back into service.

I can't ignore the wheels. I'm going with the older 4" rims because I can't find tires for the 3.5" Centerlines that take advantage of the narrower width. I ground off the heads of the rivets that retain the hubcap clips and drove out the rivets, thereby taking the clips completely off. This will let me refinish the wheels for a better look, better fitting of the tire on the wheel, and, with the clips gone, will improve the aerodynamics - and help my top speed.

...All of this and I _still_ haven't even touched the steering, suspension or brakes! Thankfully, I have all the parts on hand, but this is "cutting it close" to say the very least - to say nothing of electrical wiring and upholstery! Windshields! Oh Joy!

Lots of work but I'm enjoying it. And, imagine, doing the bodywork, paint work, interior, front axle, brakes, transaxle engine - even more than a little engine _design_ work; the satisfaction factor is _very_ high! Will I make it in time? Who else is going to show up, what engine division will they run in, and how well will they do? I'm looking forward to September!

Richard