Copyright © 2007 - 2025, Coachworks For contact data Click Here.

Copyright © 2007 - 2025

Copyright © 2007 - 2025,

Coachworks For contact data

Click Here.

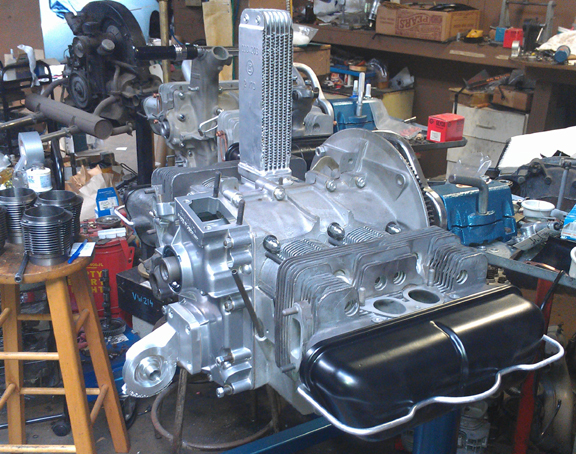

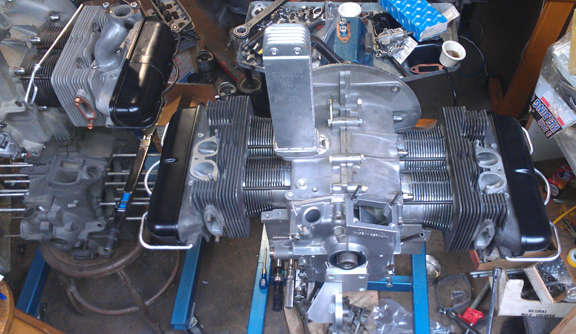

AT RIGHT: Yes, those are the black annodized SC heads mounted on genuine SC / 912 biral cylinders!

This 1963 356 SC engine came to me as a "core" and has just undergone a complete overhaul, and is fully balanced for smooth running, long life, and a few more HP.

This engine is being prepared in long-block form, with a few extra goodies, but may be purchased complete, ready to install, with only a few days delay. This engine may optionally, on customer request, be delivered "run-in" as per Porsche factory specifications as outlined in the Workshop Manual, operations 52 EN, 53 EN, and 54 EN, pages E83 and E84.

SPECIAL NOTICE

This web page is still under construction! This disclaimer will be removed when all the images and text work has been completed.

Meanwhile, the contents are reasonabley accurate, just incomplete.

AT

RIGHT: The lighting makes the cylinder heads look a bit pale, but they're

genuine SC, and are seen a bit better below. The oil cooler is the original

that came with this engine from new and it has not been restored!

AT

RIGHT: The lighting makes the cylinder heads look a bit pale, but they're

genuine SC, and are seen a bit better below. The oil cooler is the original

that came with this engine from new and it has not been restored!

This engine has genuine SC everything - heads, crankshaft, case, etc, and all the parts are in great condition. This engine has a "standard / standard" crankshaft, and beautiful crankcase. The crankshaft bore is a perfect standard. The timing cover doesn't have any match numbers in it - that happened sometimes in this era, but it has type number 616/16 (SC) stamped into the main half pairs and the timing cover has a December '63 SC serial number.

Of course this engine has the late-type oil pump, late rockers, etc. It was even fitted with stock SC / 912 pistons and cylinders - these days quite rare in serviceable condition!

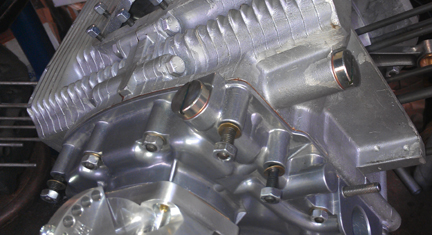

AT

RIGHT: The gadget on the oil pump cover is a full flow oil filter that takes

the oil from and returns it to the pump cover. It's made by Precision Matters.

Also note the long studs on the lower timing cover positions: This engine was

originally fitted with a "European Heater."

AT

RIGHT: The gadget on the oil pump cover is a full flow oil filter that takes

the oil from and returns it to the pump cover. It's made by Precision Matters.

Also note the long studs on the lower timing cover positions: This engine was

originally fitted with a "European Heater."

This engine has undergone a thorough rebuild as described herein. Every detail about the engine has been attended to; nothing was ignored.

I got this engine from a friend who lives down in the LA area where he grew up. He had a friend who ran a wrecking yard in the Long Beach area and he explained that in the mid 1970s a 356 SC had been wrecked, his friend called telling him about it, and he got this engine from that car for a dune buggy project.

He says he installed it and ran it briefly a few times in the buggy, but he never figured out the clutch and throttle situation and gave up on the whole project. He kept the engine, sold the buggy, and stored the engine in the back of his garrage until he conveyed it to me. I got it for possible use in my own SC but before the day came to install it, I had the good luck to finally get my car's original engine, so this became surplus to me.

Unfortunately, I didn't think to take "before" photos, or of the tear down - or if I did, I don't know where they are as that was back in the age of film cameras!

This crankcase is in great condition! It's standard. It needed nothing but a good cleaning, and even then, it wasn't really dirty.

The crankshaft that came with has been replaced with this one:

As usual, I mounted the crankshaft up on the ole crankshaft stand and mounted up the rods. The red mark indicates that I also magnifluxed the crankshaft to check for cracks and then rotationally balanced it!

I thoughtfully replaced the connecting rods that came with the engine with one of the last few of these sets at right. All these are "late type", the best of the breed. All have been rebuilt carefully. I rebuild rods in batches - it's easier / faster / cheaper that way as it keeps setup time to a minimum.

For

me, "rebuilding the rods" means to:

For

me, "rebuilding the rods" means to:

This is all standard work so there aren't any photos of them in-process.

Also worth pointing out here that I refaced the cam followers, just to be sure they wear-in correctly, though it was probably unnecessary, and you can see them as the case halve go together...

Now, time to put the case halves together! Prep-work done correctly, this goes easily and quickly and the story is best told in images. Note that I used genuine 14mm ATF (across the flats) bolts and nuts, and 12mm ATF nuts on the timing cover, all replated in clear cadmium.

As described earlier, I was planning to use this engine in my own SC, so I machined the timing cover for use of the Precision Matters full-flow oil filter system European version to accommodate the European heater system. After having done that and gotten the cover, I thought I'd go ahead and dedicate them to this engine, so you get a bonus!

That goes rather quickly, the timing cover goes on, and here we have it as a "bottom end:"

Cylinder

Heads

Cylinder

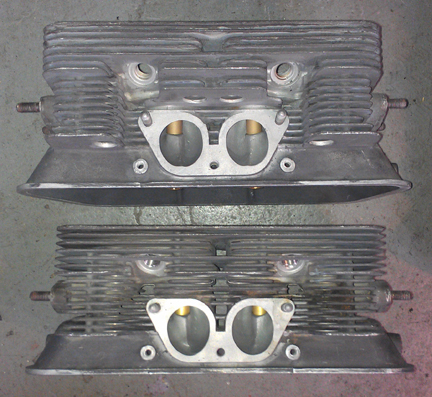

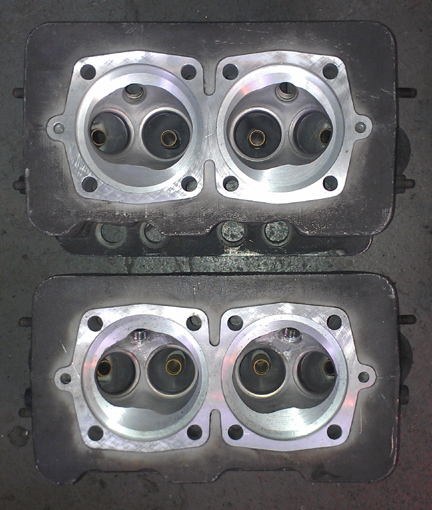

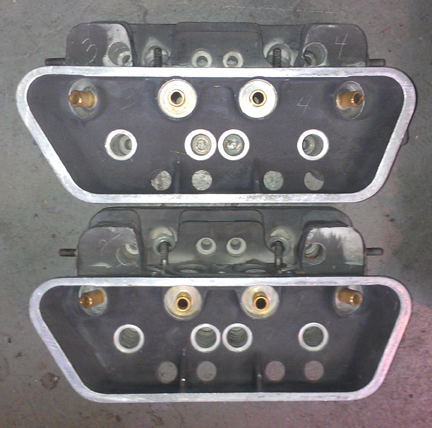

HeadsOverall these heads were very nice, no cracked fins or stripped threads, for example, and SC heads are remarkably rare - the black anadizing is unique to them and the S90, and it can be (and sometimes is) mistakenly media-blasted away! The black shading increases the emmisivity of the head by about 9%.

Unfortunately, one cylinder head had cracks in the combustion chambers. This is, also unfortunately, not rare at all; all the late type heads, from C onward, are prone to cracking between the spark plug hole and the valve seats, and sometimes between the two valve seats. Thankfully, most of the time such cracks are easy to repair:

That work was done on the lower head pictured here - new guides in both heads. And in this instance, the upper head also needed the deck surfaces refaced so it happens that they match very well, it's just one had cracks and the other didn't.

Fitted to these heads are great valves. They're originals, not aftermarket replacement which are all you can get new today. Further, and vitally, the exhaust valves ARE the sodium filled type, which haven't been available new for some years now. Of course, the valves have been checked for length (stretching makes them unworthy), polished, and refaced, so they're effectively perfect.

New

springs, of course, carefully selected.

New

springs, of course, carefully selected.

Previously, we went through a large batch of about 40 new springs and they were grouped by strength. We match up slightly stiffer springs with the heavier valves (intakes are about 2% heavier than exhausts), so they're very close sets, matched up, so all the valves tend to float at the same time. ...Of course, each valve and retainer are position-specific through the shimming process...

AT RIGHT: The upper head had no cracks, but if you look carefully, you can see that the lower head had a crack in each combustion chamber between the spark plug and intake valve seat which has been repaired.

After the valves are fitted, the combustion chambers are measured with a burrette. Remarkably, all four combustion chambers measure 58.6ml - it's pretty rare that both in one head match exactly, much less two heads, one with new seats, but I attribute this to the fact that they had little wear on the original seats or valves, so they fill the chamber identically (as new).

AT LEFT: Here you can see the new valve guides quite nicely.

Original

SC / 912 cylinders in runnable condition are quite rare today because the process

of casting the aluminum fins over the iron liner during the manufacturing process

naturally anneals the iron liner, so it's softer than it's all-iron cylinder

counterpart, and thus wears faster. And so by now, fifty years later, nearly

all of them are worn out! However, we took the original four and added them

to our stash of them and prepared three set worth, cleaned them carefully, honed

them and then selected the smallest internal diameter four to serve in this

engine. Here they are.

Original

SC / 912 cylinders in runnable condition are quite rare today because the process

of casting the aluminum fins over the iron liner during the manufacturing process

naturally anneals the iron liner, so it's softer than it's all-iron cylinder

counterpart, and thus wears faster. And so by now, fifty years later, nearly

all of them are worn out! However, we took the original four and added them

to our stash of them and prepared three set worth, cleaned them carefully, honed

them and then selected the smallest internal diameter four to serve in this

engine. Here they are.

AT RIGHT: Three sets of SC / 912 cylinders, cleaned, honed and ready to go.

We always check the match pistons to cylinders and match piston weights as a set, and provide any remedial action to correct any errors before installation. For example, by shuffling around the piston pins among the pistons, one can usually improve the matching of piston weights. This set naturally balanced (without removing material) to within 0.3 grams - the official specification is ten grams (10g) - with three of them at the exact same weight (458.5g) and one a little lighter.

For many shops, from this point, installation goes very quickly, but we think this is where one needs to take one's time! The key reason one needs to take time here is that there are production tolerances on every part in an engine, and while a set of parts may look identical, there's often subtle variation between members of a set, and there are sometimes significant errors in production that weren't caught by the manufacturer's quality control processes. These errors can "stack up" and cause problems if not discovered and corrected.

Here's our process: Two of these steps require special tools most shops don't have.

We like to carefully measure everything and then mix-and-match the parts for superior fit. We have also discovered significant manufacturing errors with this process which would likely have gone unnoticed without these measures. It is remarkably easy, for example, to overlook the circumstance of the crankshaft bore not in the true center of the crankcase, angled on the horizontal left or right of center, or not on the same horizontal plane at all. Yet examples of errors like these are not as uncommon as we would like.

Here you can see them being fitted for height comparison check - this is done to ensure that there are no difference between the cylinder heights that the head itself "sees." The book value for tolerated error is 0.1mm (four thousandths of an inch), but in this case, <INSERT MEASUREMENT DATA>

The next thing we do is something nobody else does (that we know of) in the engine building process, and that is to measure the height the piston crown comes above the plane of the top of the cylinder. I call this the CAC, or "Crown Above Cylinder." This value is important because, firstly, it can reveal deeper problems, and because it helps us get the compression ratio equal in all four cylinders.

Here are some of the deeper problems that can be discovered through a CAC check:

In order to do this for these engines, you have to have special tools. Here, you can see them in action on this engine in the two images above.

Even if you can't read the needle in these images, you can tell that <INSERT MEASUREMENT DATA> The distance between the smallest tick marks is one hundredth of a mm, or 0.0004", and you can discern to perhaps a tenth of that! So, this is a very accurate measure, performed while the cylinder is under torque, so any shims are squished flat, etc.

The accuracy is so good, that if you take the time to swap parts around, you can accurately determine discrepancies in the manufacture of the various parts! But, we ARE splitting hairs here! However, a benefit to both engine builder and customer is that the ability to move parts around for better fit means that perfection is more easily achieved, and the more equal the HP production of each cylinder, the smoother the engine will run, and the more HP the engine will produce overall.

Because this process includes the entire assembly, torqued as in service, and measures the height each piston protrudes out of its cylinder, all errors in connecting rod lengths, cylinder heights, crankcase spigots depths (cylinder bore deck), piston connecting pin heights, and shim thickness' are accounted for in the measurement results. There is no superior method.

At

this point the engine is ready for its cylinder heads, and this work went very

quickly - as it should! - as all the prep work was already done.

At

this point the engine is ready for its cylinder heads, and this work went very

quickly - as it should! - as all the prep work was already done.

AT RIGHT: The oil control pistons were replaced with new pistons, springs, and even the retaining caps and, of course, their seals. The full-flow oil system can also be seen here, as well as the European Heater length studs (bottom outer four on the timing cover).

Prepare the head "bolts" and washers, prepare the pushrod tubes, prepare the lower cylinder air deflection plates and their wire retainers, and get the torque wrenches set, and bolt on those heads!

My pattern is to mount one head, torque it to 7 ft lbs (as per the manual), then mount the other head the same way, and then alternate between the heads with an ever-increasing torque up to the final torque value, then repeat the final value until the fasteners no longer turn when torque is applied.

OK,

mount the valve gear, adjust the valves and pop on the valve covers.

OK,

mount the valve gear, adjust the valves and pop on the valve covers.

Then fit the oil drain plug, and sump screen and plate. Of some small note is that all the sump studs are original and in fine condition. I used new cap-nuts to protect the studs into the future.

Then, fit the two oil control pistons.

I decided to let the original oil cooler go with this engine - after cleaning, of course! It's virtually perfect, and was NOT restored - that's just how good it is!

And now here it is as the longblock, ready for pickup or delivery!

NOTE: If this engine is sold as a long-block... One should NOT install the distributor drive gear without also installing a distributor because if anyone rotates the engine backwards, it will push the drive gear up where it can damage the bronze drive gear! Therefore, the distributor drive is NOT mounted until the last reasonable moment!

Because some people are keeping logs of VIN and engine numbers and then purport to tell people what someone else has, out of respect and concern for a buyer's privacy, exact VIN and engine number data are not published here.